From MIG and TIG welding to surface grinding and Wire EDM, our comprehensive capabilities ensure we can meet your needs with precision. Whether you need advanced CNC bending, CO2 laser cutting, or custom machining services, Fremont Cutting Dies is your one-stop shop for superior quality.

Welding

Welding is essential for creating strong, durable structures. Our welding services include MIG and TIG welding, exclusively applied to our own products. Our welding services include MIG and TIG welding applied to our own products. We possess the capability to weld a wide range of materials, ensuring high-quality results for any of your welding needs.

Auto Bending

Auto bending involves the automated shaping of metal parts using Computer Numerical Control benders, which is crucial for creating precise, consistent bends in metal components. We utilize state-of-the-art CNC benders to manufacture all our steel rule dies, ranging from 0.937″ to 2″ in height and from 2pt to 4pt in thickness.

CO2 Laser Cutting

CO2 laser cutting is a high-precision process ideal for producing intricate designs with exceptional accuracy. Our CO2 laser cutting technology is engineered for precision blade kerf, capable of cutting both thin gauge mild and stainless steel. For low production runs, we can process various substrates directly, eliminating the need for a physical cutting die.

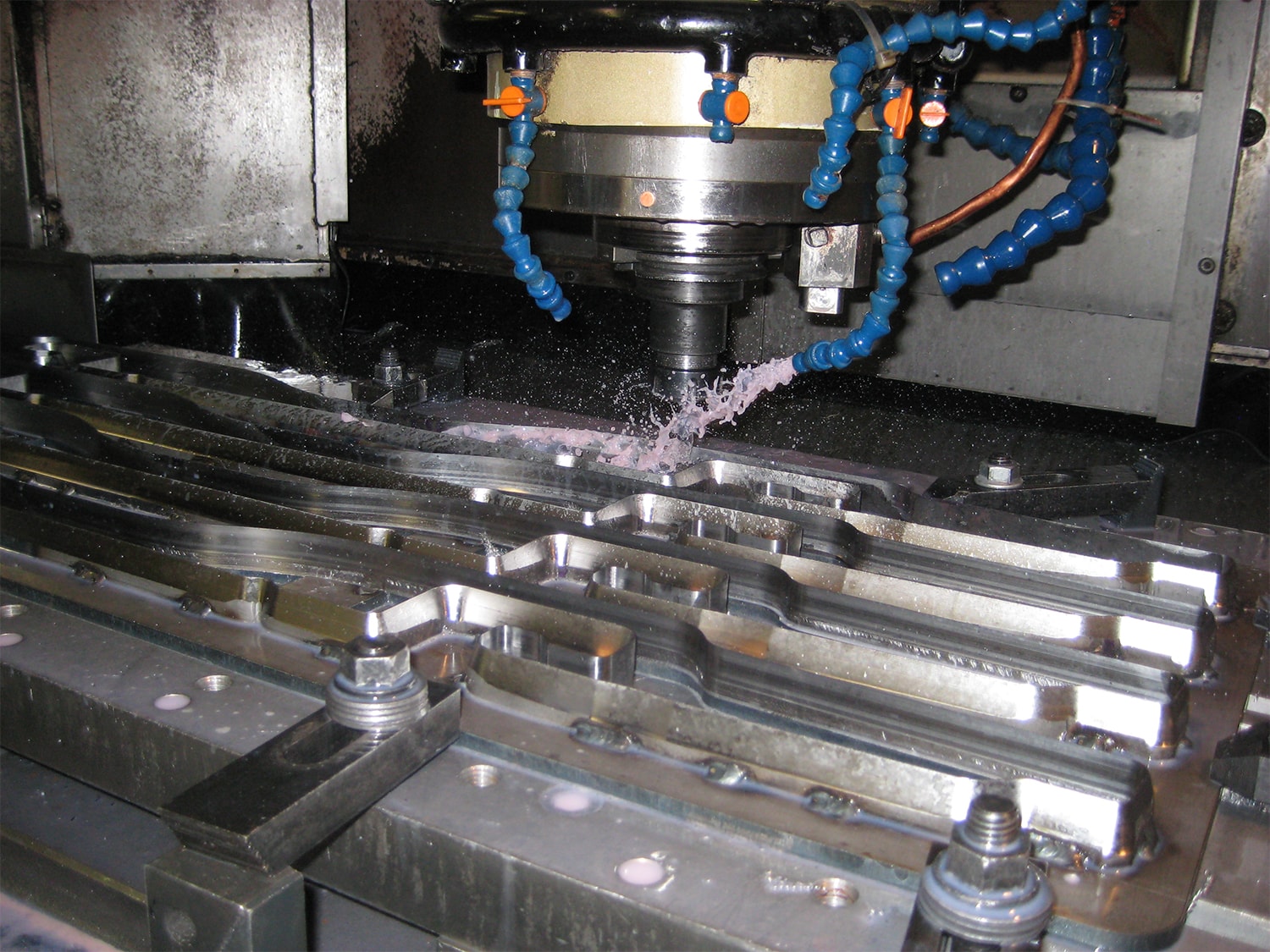

Die Machining

Die machining involves the precise cutting and shaping of metal parts to create dies used in various manufacturing processes. This is essential for producing custom tooling and components with exact specifications. We not only machine all the components for our own tooling but also offer custom machining services based on customer specifications. As long as the dimensions fit our equipment, we can fabricate virtually any part.

Surface Grinding

Surface grinding is a finishing process that involves the use of a rotating abrasive wheel to create a smooth, flat surface on a workpiece. Our surface grinding services feature a 16″ x 32″ chuck and a table load capacity of approximately 1,500 pounds. This capability ensures precision surface finishing and thickness control, making it the ideal solution for achieving consistent surfaces.

Steel Fabrication

Steel fabrication is the process of cutting, bending, and assembling steel to create custom structures and components. This capability is vital for producing everything from simple parts to complex assemblies used in various industries. We specialize in custom steel fabrication, producing a variety of products including work-in-progress racks, tables, carts, and custom weldments.

Bridgeport

Bridgeport milling machines are versatile tools used for handling small, detailed projects with precision. Bridgeport mills are particularly valuable for creating small, intricate parts, performing drilling, slotting, and cutting operations. In our lineup of machinery, we have several Bridgeport milling machines for handling more simplistic, one-off projects. These machines are integral for tasks requiring high precision and flexibility.

Filing

Filing is a manual process used to smooth and refine metal surfaces. This technique ensures that the components meet strict quality standards and are free from imperfections. Filing is completed at the end of our production process for our in-house product line. It is a critical step in our process, ensuring that each project is completed to the highest standards of precision.

Blanchard Grinding

Blanchard grinding is a type of rotary surface grinding that uses a large grinding wheel to remove material from one side of a workpiece, producing a smooth, flat surface. We offer in-house Blanchard grinding with a 42″ chuck, providing large-scale grinding capabilities for a uniform, high-quality finish for large components.

Wire EDM

Wire EDM (Electrical Discharge Machining) is a precision machining process that uses a thin wire to cut intricate shapes out of metal. Our Wire EDM machine features a travel capacity of approximately 17″ x 24″ x 12″, allowing us to cut intricate shapes with exceptional precision. This capability is essential for producing complex parts with tight tolerances.

How We Are Different

Fremont Cutting Dies stands above the rest with our comprehensive, one-stop-shop experience for cutting die and fabrication. We maintain complete control over quality and service by manufacturing our products in-house, meaning you receive superior results each time.

Our range of capabilities, from Auto Bending and CO2 Laser Cutting to Precise Surface Grinding and Wire EDM, allows us to handle projects of any size. Whether you have a small-scale or large production need, Fremont Cutting Dies will deliver unparalleled precision.

State-of-the-art Equipment

Fremont Cutting Dies utilizes everything from manual to fully automated equipment in our processes. A quick sampling of our equipment includes; Vertical Milling Machines, Bridgeports, CNC Lathe, Manual Lathe, Wire EDM, Surface Grinders, Blanchard Grinder, CNC Rule Processor, Manual Bending Equipment, and Hydraulic Bending Equipment.

Quality Control

Quality is something that Fremont Cutting Dies takes very seriously. We have our own strict internal quality guidelines that are met with each and every project. All dies are checked for quality workmanship and accuracy prior to leaving our factory.

Industries We Serve

Fremont Cutting Dies serves a wide range of industries to deliver the perfect products to solve your problems. Even if you do not see your industry below, no need to worry we have served the listed industries and everything in between.

Our clients are frequently in the following industries; Appliance, Decal/Label, Automotive, Heavy Truck, Pharmaceutical, Thermo-Form, Packaging, Gasket, Foam, Filter Fabricators, and Medical.